Description

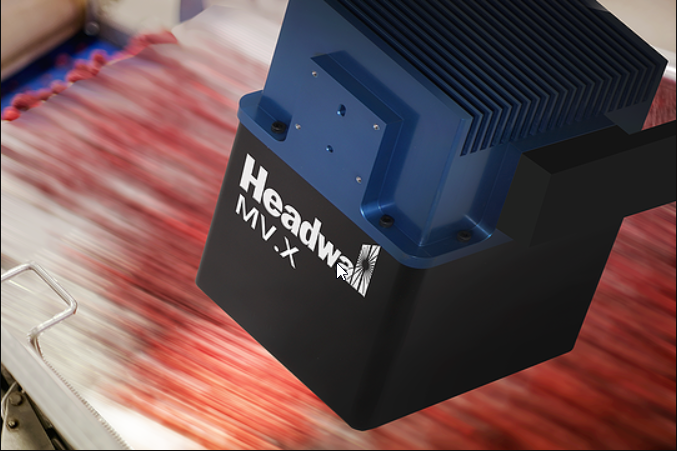

Packaged in a compact, dust-resistant and watertight housing, the Hyperspec MV.X™ is designed to be used in advanced machine vision, quality monitoring, and process analytical applications. This rugged solution can be installed in both inside and outside production environments.

Hyperspectral imaging enables food processors to apply advanced automated sorting and inspection solutions to alleviate some of the most labour-intensive tasks. Collecting highly resolved spectral information for each pixel in the image enables the detection of slight differences in color or composition to improve sorting and grading decisions.

With its impressive features, including IP rating for industrial use, coverage of 400 – 1,000 nm spectrums, and real-time spectral classification capabilities, the Hyperspec MV.X™ offers unparalleled performance. Furthermore, the system’s compatibility with perClass Mira® software and integration with industrial control systems ensure seamless operation within existing setups. Its compact form factors and multiple mounting options make it highly versatile for various installation requirements.

Technical Specifications:

| Hyperspec MV.X | |

| Wavelength range | 400 – 1,000 nm |

| Spatial bands | 1020 |

| Spectral bands | 301 |

| Spectral sampling | 2.0 nm/pixel |

| Spectral FWHM | 6 nm |

| CE Certified | Yes |

| Aperture | f/2.5 |

| Interfaces | GenICam, WebSocket

MQTT, RS-232/422, and 5V TTL in development |

| Ports | RJ45 (GigE) x2, D-Sub 26-Pin (GPIO) |

| Camera technology | CMOS |

| Bit depth | 12-bits |

| Max PWR Consumption | < 42 W |

| Power Input / Input Voltage | 12-30 VDC |

| Weight (with 24-mm lens) | 3 kg/ 6.6 Ibs |

| Dimensions (L x W x H) | 255 x 136 x 136 mm / 10.0 x 5.4 x 5.4 in |

| Operational Temp Range | 0 deg C to 50 deg C |

| Storage Temperature Range | -10 deg C – 60 deg C |

Interested in the Hyperspec MV.X ™? Request a quote or call us on +44(0)1954 232 776 to discuss your requirements.