Description

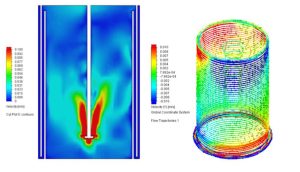

Conventional vs Laminar Reactor: Uniform mixing illustrated by LFD comparison with conventional stirred tank

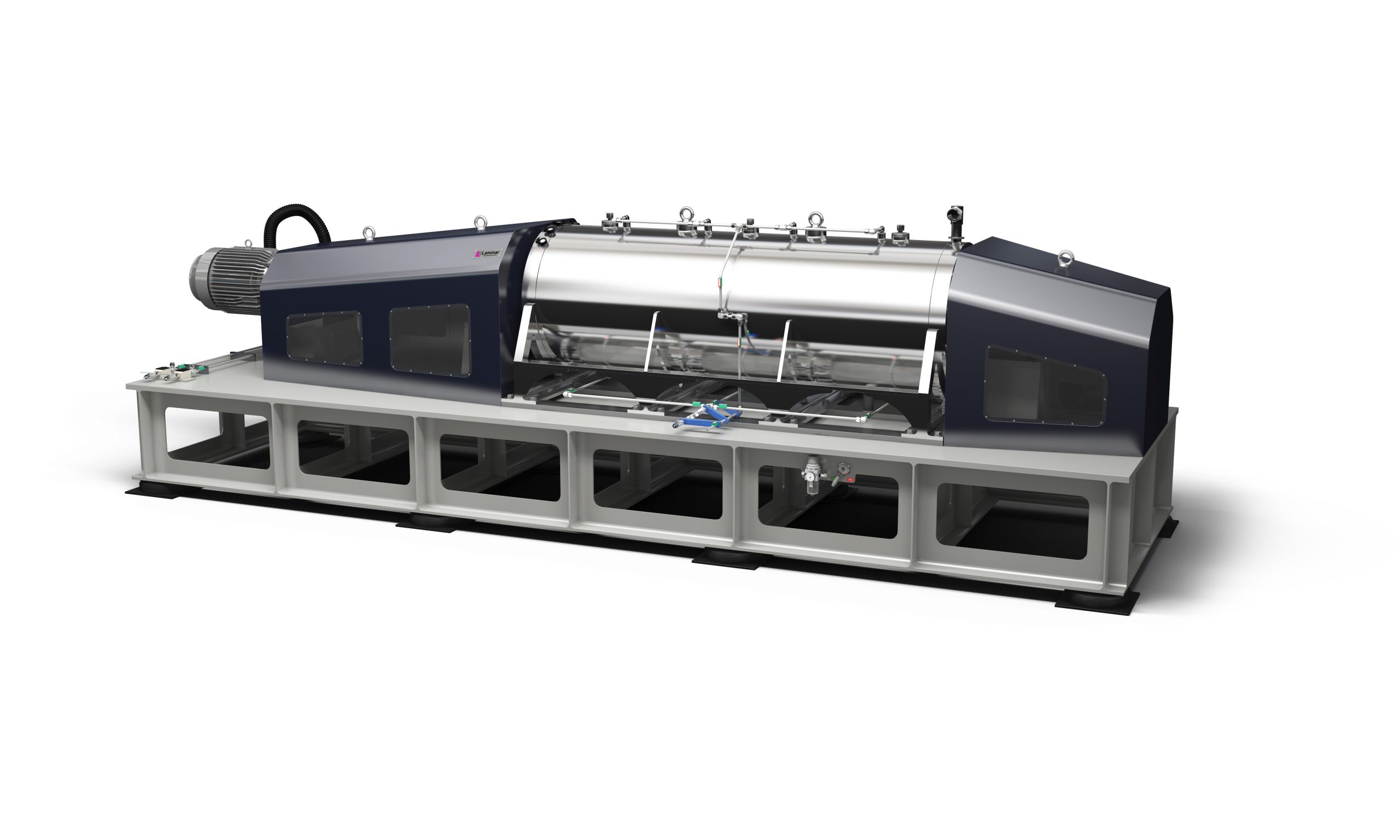

Laminar Continuous Taylor Reactors (LCTRs) are a patented chemical reactor series that produce high-purity, uniform substances using Taylor Fluid Flow.

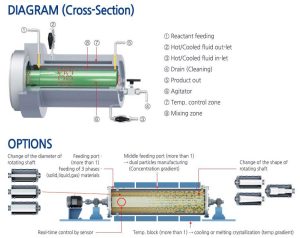

LCTRs use a jacketed cylindrical vessel with a central, rotating agitation bar to produce taylor flow mixing along the length of the vessel. Reagents are pumped at a controlled rate into the vessel and the reaction efficiency is maximised through specific turbulent mixing before the products are collected at the end of the vessel.

Advantages of Taylor Flow Reactors

- Flow reactor designed around exploiting specific turbulent mixing through Taylor flow

- Higher mixing force and mass transfer velocity than conventional batch reactors

- Combines the advantages of tank and tubular type reactors in the production of high-purity materials under continuous flow

| Model | Volume (L) | Dimension (L/W/H) | Max. Agitation Speed (rpm) | Weight (Kg) |

| Mini – V | 0.02 | 274 X 525 X 617 | 1,500 | 40 |

| Lab II – V | 0.1 | 500 X 500 X 1, 178 | 1,500 | 85 |

| Lab II – H | 0.2 | 1,102 X 450 X 574 | 1,500 | 120 |

| Tera 3100 (General) | 1 | 1,470x 700x 1,157 | 1,500 | 450 |

| Tera 3300 (PLC, CE Certified) | 1 | 1 ,400 X 700 X 1 , 1 50 | 1,500 | 650 |

| Peta | 10 | 2,330 X 700 X 1,220 | 1,500 | 1,200 |

| 50 | 3,400 X 1,300 X 1,600 | 1,200 | 3,000 | |

| Exa | 100 | 5,800 X 2,300 X 1,850 | 300 | 5,000 |

| 500 | 6,500 X 2,500 X 2,000 | 250 | 15,000 | |

| 1,000 | 8,500 X 3,000 X 2,300 | 250 | 25,000 |

Interested in the LCTR series? Request a quote or call us on +44(0)1954 232 776 to discuss your requirements.