Description

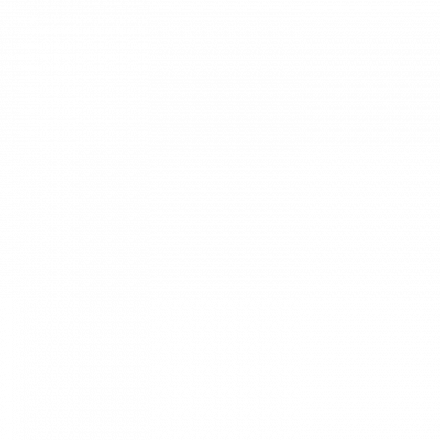

The M-700 series of Microfluidizer® processors have proven to be cost-effective in a broad range of industries including: pharmaceutical, biotechnology, chemical, coatings, inkjet inks, cosmetics and food additives. Utilising patented Microfluidizer® technology, these processors deliver the finest and most uniform distribution of submicron particle size at the highest shear rates available with no other processing technology able to match results.

The M700 series machines have high-pressure, multi-slotted fixed-geometry interaction chambers that impart identical high shear rates to product formulations as are achieved on lab-scale interaction chambers. The M7125 and M7250 models generate up to 30,000 psi operating pressure (40,000 psi available as a special option) for premium results at an affordable cost.

Technical Specifications:

| Description |

M-7125

|

M-7250

|

||

| Pressure Range |

up to 40,000 psi (2755 bar)

|

|||

| Flowrate @ 25 strokes/min | 10K- |

2.06 gpm (7.78 lpm)

|

4.13 gpm (15.6 lpm)

|

|

| 20K- |

1.05 gpm (3.96 lpm)

|

2.11 gpm (7.97 lpm)

|

||

| 30K- |

0.67 gpm (2.53 lpm)

|

1.35 gpm (5.10 lpm)

|

||

| Feed Temperature |

Maximum 165°F (75°C)

|

|||

| Product Temperature Limit |

73ºC (165ºF)

|

|||

| Power Requirements |

3 phase electrical service, 208/230/380/460/575V

|

|||

|

25 HP (18.5 kw)

|

50 HP (37 kw)

|

|||

| Utility Requirements |

Cooling water for hydraulic oil heat exchanger and process

fluid heat exchanger, compressed air (50-150 psi 1 scfm@ 50 psi, pressure dew point of 0-35°F) |

|||

| Dimensions W x D x H |

29″L x 71″W x 57″H (74 x 180 x 145 cm) |

|||

| Weight |

1,700 lbs (765 kg)

|

2,000 lbs (900 kg)

|

||

Interested in the M-700 Microfluidizer® Processor Series? Request a quote or call us on +44(0)1954 232 776 to discuss your requirements.