Particle Size Characterisation by Differential Centrifugal Sedimentation (DCS)

An Introduction to Particle Size Characterisation by DCS

By Dr Hiran Vegad

Do you know the real size of your nanoparticles?

An Introduction to Differential Centrifugal Sedimentation

Differential Centrifugal Sedimentation (DCS) is a novel and innovative, yet simple particle size characterisation technique, which has become ‘reborn’ in recent years. Previous limitations and difficulties with the technique of sedimentation have been overcome using recent advances in technology, and some smart thinking regards instrumentation and disc design. DCS is now a powerful tool in measuring nanoparticle size distribution down to around 2nm. With the unique ability to resolve very close multi-modal particle distributions, and to distinguish extremely small shifts and changes in particle size, DCS is once more gaining in popularity. The practical range of the technique is from around 2nm right up to 80 microns (exact range will be dependent on density), however the real benefits over and above more traditional nanoparticle sizing techniques (such as Dynamic Light Scattering (DLS)) are generally noticed below around 300nm.

Benefits of DCS for Nanoparticle Size Analysis

There are a number of distinct benefits associated with the DCS technique; these will be illustrated in the following section:

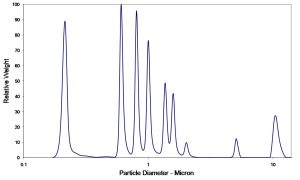

- Ultra High Resolution Capability – detect, measure & resolve peaks which differ in size by as little as 2% (Fig. 1)

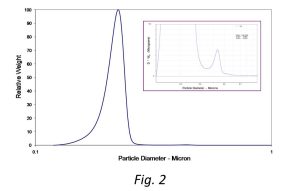

- High Sensitivity – detect & measure extremely small and subtle changes in size distributions e.g. small additional peaks (Fig. 2)

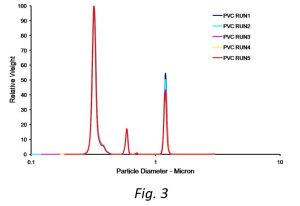

- Accurate, Reliable & Reproducible Results – traceability & calibration to NIST particle size standards (Fig. 3

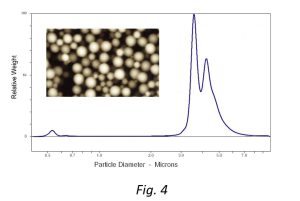

- Results that are Comparable to SEM / Microscopy Analysis (Fig. 4)

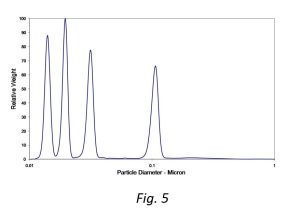

- Quantitative Analysis to give Weight & Number Distribution (Fig. 5)

DCS Particle Size Analyser Instrument Design

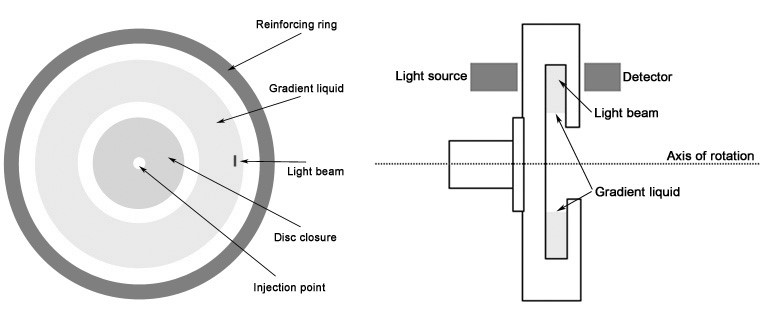

The most common design for DCS instruments is a hollow, optically clear disc that is driven by a variable speed motor. A typical disc cross section is shown in Figure 6. The detector beam is usually monochromatic light of relatively short wavelength (400 nm – 500 nm); as this gives better detector sensitivity when particles smaller than 100 nm are measured.

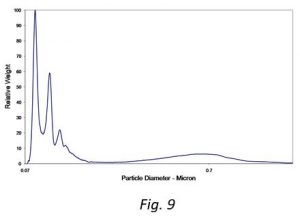

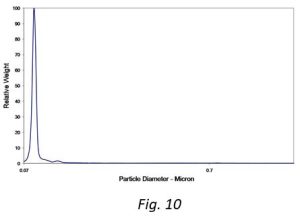

Advances in modern instrument design have enabled compact, desktop disc centrifuges capable of 24,000rpm. This enables very short analysis times for even very small nano particles; for example, the adenovirus data shown in Fig. 9 and Fig. 10 was measured in less than 10 minutes for each sample.

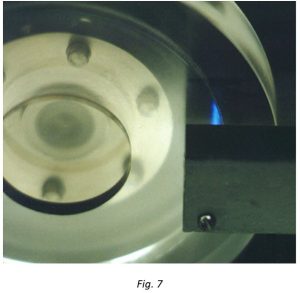

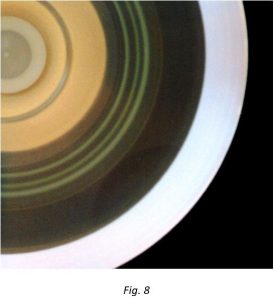

Figure 7 shows a centrifuge disc inside an instrument and the light source-detector towards the outside of the disc. Figure 8 shows the same disc in rotation during an analysis, the separated bands of differently sized particles can clearly be seen as they approach the detector.

Operation

In summary, typical routine operation of a DCS system is simply:

- Set the centrifuge at the correct speed, based on particle size and particle density (usually by retrieving an existing preset methodology from the software)

- Fill the centrifuge chamber with appropriate density gradient fluid

- Calibrate the instrument by running a calibration standard

- Run samples

Prominent Solutions

There are a number of applications that benefit particularly well from the DCS technique, these include:

- Resolve Aggregates and Agglomerates – A mixture of single adenovirus particles (Fig. 9) and multiple aggregations of the same adenovirus particles (Fig. 10) can be easily resolved as can be seen in these examples.

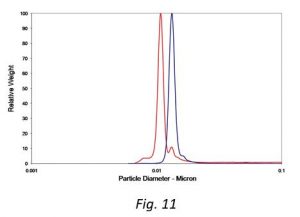

- Characterise Coating of Nanoparticles – Ability to measure/monitor coating thickness (Fig. 11)

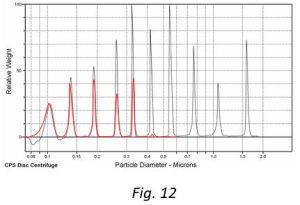

- Determine pore size distribution – Able to test a 0.4 micron filter with a latex ‘Multistandard’ (Fig. 12)

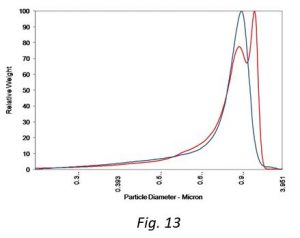

- Follow cell disruption experiments (Fig. 13)

Typical Applications

There are a wide range of applications for which the DCS technique can be applied; here are a few of the more typical:

Pharmaceutical and Biological:

- Virus and virus-like particles

- Cells and cell fragments (culture)

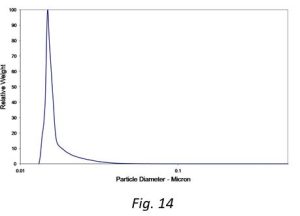

- Protein clusters (Fig. 14)

- Liposomes

- Micro encapsulated drugs

Chemical:

- Polymer latexes and emulsions

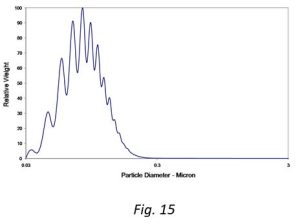

- SiO2 dispersions (Fig. 15)

- Fillers (CaCO3, clay, barites, etc.)

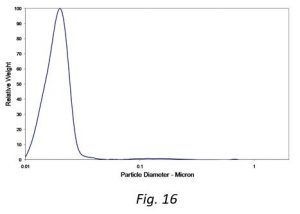

- Abrasives of all types (Diamond – Fig.16)

- Carbon Nanotubes

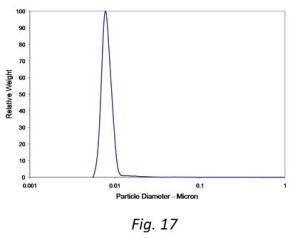

- Quantum dots (Fig. 17)

Printing and painting:

- Pigments – water and oil based

- Micro-fiber paint viscosity modifiers

- Printer/copier toner powders

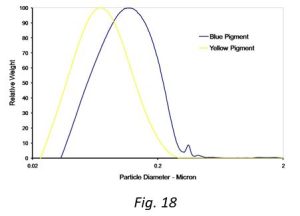

- Inkjet inks. 18 shows two overlaid particle size distributions on yellow and blue inkjet pigments. Note the small resolved peak on the leading edge of the blue pigment which could be significant regards possible jet clogging problems.

- Carbon black

- Magnetic iron oxide

DCS – An Overall Conclusion

Differential Centrifugal Sedimentation is an extremely powerful tool for high resolution particle characterisation, especially in the size range 0.002 micron (2nm) to 10 micron. It enables very narrow distributions of particles differing in size by less than 2% to be resolved, and hence extremely small differences, changes or shifts in particle size to be accurately and reproducibly detected and measured. The new method mentioned in this article for measurement of low density, neutral buoyancy particles, addresses the only previous technical limitation of DCS. Advances in recent instrumentation, have also overcome previous issues with the technique with respect to ease of use, speed of analysis, accuracy and multiple sample measurement.

The CPS DC24000 Ultra High Resolution Particle Size Analyser

The CPS DC24000 UHR is an effective analytical tool for ultra high resolution, high accuracy particle sizing. Highly poly-dispersed particles can be measured in the size range of ~3.0nm to ~60 microns, at 2 to 10 times better resolution than any other particle sizing instrument, regardless of measurement technique. Find out more by clicking the button below.