Analytik reports on the use of a GeSiM Nano-Plotter system at the University of Greenwich

Analytik reports on the use of a GeSiM Nano-Plotter system at the University of Greenwich

Analytik reports on the use of a GeSiM Nano-Plotter system at the University of Greenwich

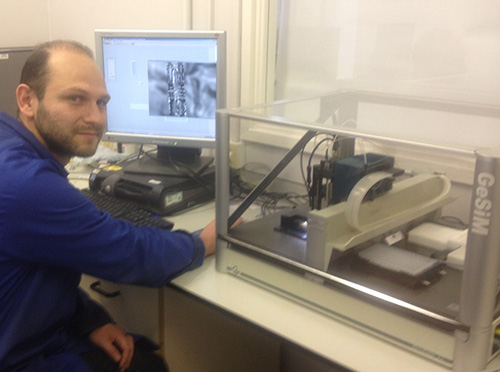

Cambridge, UK, 12th November 2013: Analytik, leading suppliers of innovative analytical instrumentation, report on the use of the GeSiM Nano-Plotter™ system at the University of Greenwich to study polymeric coatings for medical devices.

Dr Dennis Douroumis is a Reader in pharmaceutical sciences in the Faculty of Engineering and Science at the University of Greenwich. His research covers several areas: from the development of drug delivery systems applying nanotechnology to medical devices where he is working on drug eluting stents with coatings using novel polymers. This latter program employs the GeSiM Nano-Plotter from Analytik.

Dr Douroumis’ research objective is to employ ink-jetting and more specifically the Nano-Plotter for the development of polymeric coating on medical devices. These applications include the deposition of drug-polymer coatings on drug eluting stents for the treatment of cardiovascular diseases or vaccine coatings on micro-needle arrays for transdermal delivery.

Prior to discovering the Nano-Plotter system, the group used various jet-dispensing techniques. They changed to the Nano-Plotter because of its excellent performance to dispense very small amounts of coating solutions with high precision by targeting the desired substrates. A specially engineered motor rotating stent holder on the platform is used to hold and spot the drug on the cylindrical stent structure. The coated formulations are accurate, and reproducible, the resulted coatings are uniform without defects and the nanolitre dispensing process results in high yields of the active substances.

Describing his experience in using the GeSiM system, Dr Douroumis says “The Nano-Plotter provides excellent control on the droplet particle size while the system is fully automated to control the process at every step. From our experience, it is the only device that can produce the smallest droplet sizes. The software allows the design of accurate coating patterns by developing the appropriate logarithms. The process includes a cleaning step at the end of each coating run which reduces the possibilities of nozzle’s clogging.”

To find out more about GeSiM’s non-contact piezoelectric nanolitre dispensing and micropipetting systems, visit: https://analytik.co.uk/product/non-contact-nanolitre-dispensing-nano-plotter/