Microlyser™ Cell Disruptors for Effective Cell Lysis

Microlyser™ cell disruptors are perfect for rupturing a diverse range of cell types. Leveraging advanced Microfluidizer® Processor technology from Microfluidics, these disruptors achieve cell lysis at lower pressure rates compared to other methods, enhancing instrument reliability, longevity, and reducing maintenance needs.

Microlyser™ technology empowers researchers to fine-tune process parameters for optimal rupture rates while minimizing excess energy use and preventing protein denaturation. Additionally, Microlyser™ disruptors uniquely offer cell disruption without sample foaming, setting them apart from other cell lysis techniques.

Browse Solutions for Cell Disruption below; call us on +44(0)1954 232 776 or email info@analytik.co.uk to discuss your requirements with a specialist.

The Benefits of Microfluidizer® Technology for Cell Disruption

No sample foaming

Reliable operation – no frequent seal changes

Faster Processing

Highest Protein Yield

Constant Shear Rate

Fully Scalable

Safe Operation

Cell Disruptors

The LM20 is an ideal Microfluidizer for cell disruption; digitally controlled, it has a maximum process pressure of 30,000 psi enabling it to handle the toughest cell types.

The LM10 enables extremely fast, easy and consistent processing of all cell suspensions. Digital control enables repeatability between sample batches and simple operation.

The above Microfluidizer models are the most popular for cell disruption amongst our customers’ applications, however other Microfluidizers are available.

Introducing the all new Microlyser™ Production Scale Cell Disruptor

The MP350 Enhanced Biopharma Grade Microlyser™ processor delivers up to 30,000 PSI, maximizing protein yields and ensuring high product quality in cell disruption for bacterial, yeast, and algae.

It features the same multi-slotted fixed-geometry Interaction Chambers™ as all Microfluidizer equipment, ensuring consistent results batch-to-batch at production volumes. Discover Microlyser technology >

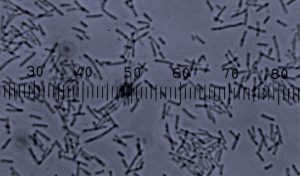

Microfluidizers handle disruption of E.Coli and other bacterial cell lines easily. Typically sufficient lysis is achieved in 1 pass at moderate process pressures, minimizing excess energy and heat in the system and enabling excellent recovery of viable protein.

Microfluidizer® Processor Laboratory Results

Contact us via info@analytik.co.uk or call +44 (0)1954 232 776 to discuss your requirements.

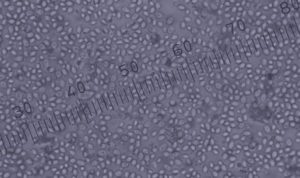

Yeast cell types are typically resilient by comparison to other bacteria and insect cells. Microfluidizer’s exceptionally high and homogenous shear rate and control of process temperature makes them ideal for processing of the most challenging Yeast species where multiple passes may be required.

Microfluidizer® Processor Laboratory Results

Contact us via info@analytik.co.uk or call +44 (0)1954 232 776 to discuss your requirements.

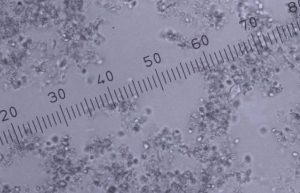

Insect cells, such as Sf9, are comparatively easy to disrupt compared to Bacteria and Yeasts; Microfluidizers enable fast, consistent processing at moderate pressures usually requiring a single pass for superior lysis.

Contact us via info@analytik.co.uk or call +44 (0)1954 232 776 to discuss your requirements.

The easiest cell type to disrupt; when required processing of these cell needs to be handled gently to preserve viral vectors such as AAVs, typically as part of a Gene Therapy production process. Mild conditions are used; yield, scalability and easy downstream filtration are among the main benefits for using Microfludizer technology for this application over freeze-thaw or chemical lysis methods.

![]() Microfluidizer® Technology in Cell Lysing for Gene Therapy

Microfluidizer® Technology in Cell Lysing for Gene Therapy

Contact us via info@analytik.co.uk or call +44 (0)1954 232 776 to discuss your requirements.

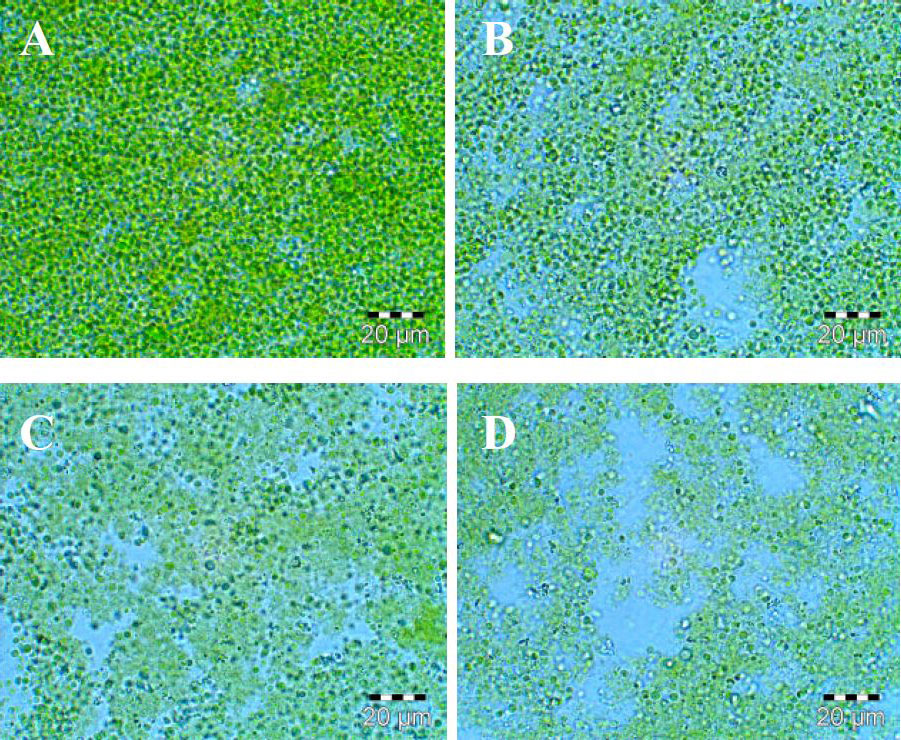

Algae cells such as Diatoms and various other naturally occurring species can be successfully lysed on a Microfluidizer with varying conditions for research, ingredient harvesting or biofuel purposes.

Microfluidizer® Processor Laboratory Results

| Industry | BioTech Company F |

| Product | A 10% wt. dispersion of algae cells suspended in water. |

| Test Objective | To rupture the cells in order to free the oil that is contained inside. |

| Processor | M-110S |

| Chambers | • G10Z (87 microns) |

| No. of Passes | 3 |

| Process Pressure | 20,000 psi |

| Process Procedure | The algae cells were suspended in water at a concentration of 15% wt. cells when they arrived. The original concentration was very viscous, such that it was diluted down to approximately 10% wt. before processing. The samples were processed on the M-110S Microfluidizer processor for one – three passes at 20,000 psi. A sample was taken after each pass and analysed. |

| Summary of Results | The optical microscopy results from the analysis can be found in Figure 1. |

Figure 1: Pictured above are optical microscopy images of BioTech Company F’s algae cell dispersion (A) before processing, (B) after one pass, (C) after two passes, and (D) after three passes with the G10Z (87 μm) IXC. All samples were processed with the M-110S Microfluidizer processor at 20,000 psi.

Contact us via info@analytik.co.uk or call +44 (0)1954 232 776 to discuss your requirements.

Our customers

The LM20 Microfluidizer processor offers superior lysis over traditional methods of cell disruption with an efficient system to reduce internal blockages. The scalability of the design means that the forces experienced by cells will not change if the sample volume increases. I can, therefore, have confidence that the sample quality, yield and processing times won’t be impacted by scaling up my lab processes.

Digital controls allow the system pressure to be set more easily and accurately compared to alternative manual processors, reducing the potential for errors and increasing reproducibility.

Analytik’s in-depth user training, and easy operation/maintenance procedures have been extremely beneficial. I feel confident to troubleshoot and perform preventative maintenance without having to call the support teams – it doesn’t feel like a ‘black box’ machine.

I would recommend the LM20 Microfluidizer as an essential tool for cell disruption.

James Wright, Protein Scientist at Abcam Plc

We approached Analytik to find a replacement for a high-pressure homogeniser from another manufacturer, which had been unreliable and failed to achieve sufficient lysis of our tough yeast cells even after very many passes. We selected the LM20 Microfluidizer not only because it efficiently lysed a broad range of cell types but also was incredibly simple and easy to use which is very important as many different people need to use the machine regularly.

We also much appreciated the knowledgeable technical and applications support provided by Analytik which has enabled us to fully exploit the considerable capabilities of the LM20 Microfluidizer.

Dr Petra Ungerer, Lab Manager, School of Biological & Chemical Sciences at Queen Mary University London

CAN’T FIND WHAT YOU’RE LOOKING FOR?

Fill out a Contact Form, call +44(0)1954 232 776 or email info@analytik.co.uk to discuss your requirements with a specialist.