What is tissue regeneration?

Bio- or Tissue Engineering sounds like something out of a science fiction novel, yet it is becoming a very real approach to medicine. Although the ability to print living functional organs is currently out of reach, it is no secret that this is the goal for biological engineers. Recent developments in bioprinting means that scientists are exploring use of this technology for Tissue Regeneration. Tissue regeneration is the regrowth of a damaged organ using part of the remaining tissue and has become a highly specialised field.

There are many applications for tissue engineering, from printing living cells to react with upcoming drugs, thereby accurately testing if they are safe for human consumption, to printing and developing regenerative tissue. The field of Tissue Engineering has the potential to revolutionise our approach to medicine.

The revolutionary potential of tissue regeneration and bioengineering is huge. By taking a 3D image of the patient, highly innovative software can design and program the exact shape of the organ or bone the patient requires. This information is then sent to a 3D bioprinter, which prints a scaffold for the cells to grow and develop. The scaffold itself is degradable, so once the tissue is formed it will disintegrate, leaving only pure tissue. Another significant feature of 3D bioprinted tissue, is that the cells are comprised from the individual patient, which will eliminate the chance of the procedure being rejected by the patient’s body.

Tissue regeneration for facial reconstruction

Researchers at John Hopkins University are developing the application of bioprinting scaffolds for facial reconstruction. This approach aims to replace the current procedure of reconstructing the patient’s facial features through a bone graft. Bone grafts involve taking bone from elsewhere in the patient’s body, i.e their leg, and using it to rebuild their facial structure through extensive surgery. This procedure often leaves patients with a significant improvement to their facial structure compared to their prior condition, yet still leaves the patient with noticeable abnormalities once the procedure is complete. In the United States, there is an annual intake of over 200,000 patients that require bone grafts for facial reconstruction. This procedure makes up a market value of over $1 Billion.

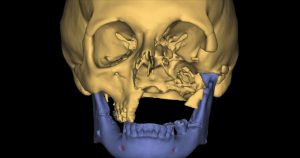

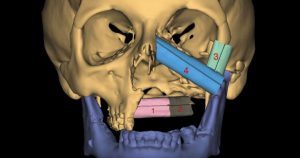

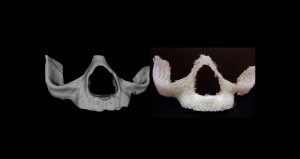

John Hopkins University’s approach to facial reconstruction revolves around tissue engineering and regeneration. Their process begins with a medical image of the patients facial structure. Once taken, the image is processed through complex software which generates a 3D model of the bone they are missing. Once this model is generated, it is printed as an exact scaffold by a 3D bioprinter.

The patient’s stem cells are then added to their scaffold. These are gathered from the patient’s fat tissue. Stem cells can provide the information to begin the regeneration of a variety of tissues. By implementing bone signals into the stem cells and scaffold, the process of bone regeneration can begin.

The scaffold is porous, meaning it is designed and printed so cells and blood vessels can grow inside of it. This will allow the growth and development of the patients living, healthy tissue. Once this tissue starts to form, so does the patient’s bone. The scaffold begins to degrade once healthy bone has formed, this will eventually leave only biological tissue composed from the patient’s own DNA. Once the process is complete, the patient will have an exact facial structure matching their original, healthy facial structure.

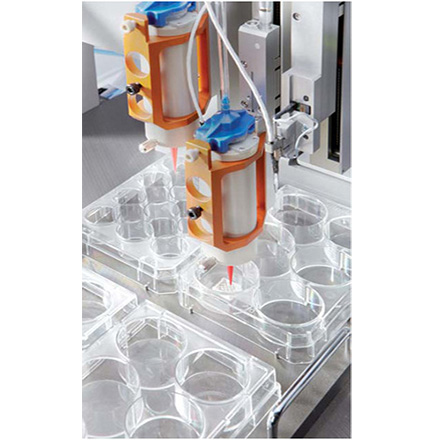

GeSiM Bioscaffolder 3D Bioprinter

The BioScaffolder 3D bioprinter is a modular instrument platform with up to four independent z-axes for running several dispensing tools. It can print a variety of pasty materials (hydrogels and biopolymers e.g. collagen, alginate, bone cement paste, polymer paste etc.) with up to three cartridges and has a unique optional heat controlled piezoelectric micro-pipetting system.

Find out more about GeSiM’s Bioscaffolder 3D bioprinter by clicking the button below: