3D bioprinting Human Bones with the GeSim Bioscaffolder

Science and medicine is progressing evermore rapidly and concepts such as body part printing and mechanical limbs, once only existent in Sci-fi novels, are becoming a reality.

Typically, in the event of an accident, bones can be replaced with titanium implants. This is a widely renowned method for trauma surgery and has proved to have benefits for those needing them. However, science is progressing at such a rate that the currently experimental treatment of 3D bioprinting has the potential to make titanium implants a thing of the past. Scientists are presenting previously unthinkable solutions to situations any of us could be unlucky enough to find ourselves in.

Troubles with Titanium solvable with the brilliance of 3D bioprinting

Despite being an established, reliable and proven method, there are some disadvantages with titanium implants, such as their mismatch of mechanical properties, interface issues to surrounding soft tissues and their inability to grow and adapt to your body.

However, the future of medicinal treatment has become significantly closer thanks to GeSim and Dresden University of Technology’s research project. The project focused on establishing 3D printing of patient-specific implants of a degradable biomaterial. The project was conducted at TU Dresden, the ‘Centre for Translational Bone, Joint and Soft Tissue Research.

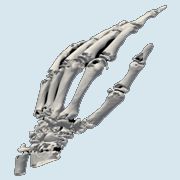

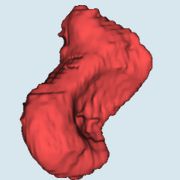

The human scaphoid was selected as a model and 3D data was then extracted from a CT scan.

The method in the madness

Firstly, the research team gathered the CT data and analysed to separate the patients bones from the remaining tissue (virtual environment/ contouring). The next step was transforming the CT data into a 3D DICOM model using an Open Source software package. The Scaphoid bone was isolated from the complete bone set to generate 3D STL data, a format describing data by triangularisation. The STL format is notoriously used by a variety of 3D printers, including the GeSiM bioscaffolder

The future is coming thanks to 3D bioprinting

Finally the STL data of the Scaphoid bone was loaded into the software of the GeSiM BS3.1. The bone model was printed from calcium phosphate bone cement VELOX® from InnoTERE GmbH, Radebeul.

This work is a research project without clinical background. Future research may be focusing on the settlement of osteoblasts or mesenchymal stem cells in the scaffold structure for subsequent incubation and generation of an artificial “living” bone.