Microfluidizer Technology used to Produce Graphene-Based E-Textiles for Wearable Electronic Applications

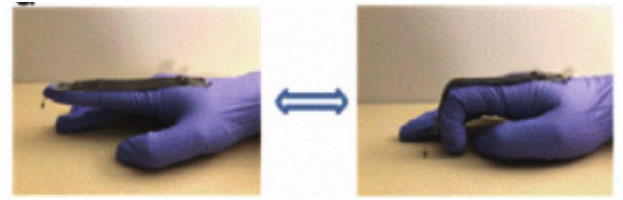

In the latest research from the University of Manchester, “highly conductive, ultra-flexible, and machine washable graphene-based wearable e-textiles are reported. A simple and scalable pad−dry−cure method with subsequent roller compression and a fine encapsulation of graphene flakes is used. The graphene-based wearable e-textiles thus produced provide lowest sheet resistance (≈11.9 Ω sq−1) ever reported on graphene e-textiles, and highly conductive even after 10 home laundry washing cycles. Moreover, it exhibits extremely high flexibility, bendability, and compressibility as it shows repeatable response in both forward and backward directions before and after home laundry washing cycles. The scalability and multifunctional applications of such highly conductive graphene-based wearable e-textiles are demonstrated as ultraflexible supercapacitor and skin-mounted strain sensors.”

Increased interest in wearable technology has led to the emergence of electronic textiles (e-textiles), a new generation of wearable devices. Integration of energy storage systems, health monitoring devices, wearable displays, and activity monitoring with everyday clothing has changed the paradigm of the next generation textiles. Existing e-textile technology often utilises complex and time-consuming specialised sewing and embroidery techniques with conductive yarns or threads, making them expensive Researchers are moving towards full integration of devices through coating or printing, which offers more flexibility and comfort to users. In addition, existing metal-based technologies are often toxic and nonbiodegradable therefore increasing the need for alternative e-textiles.

Credit: The National Graphene Institute, University of Manchester. Application of highly conductive graphene-coated, compressed and encapsulated textiles as strain sensors to detect human motion.

Graphene-based wearable e-textiles have attracted significant interest in recent years due to graphene’s excellent electrical and mechanical properties. Previous research demonstrated that reduced graphene oxide (rGO), a form of graphene, shows better adhesion to textiles and potential washing stability, a key requirement of wearable e-textiles. However, rGO suffers from poor electrical conductivity therefore making it unsuitable or applications where high electrical conductivity is required. For such applications graphene based conductive ink could be a solution however there are two main challenges with this for wearable e-textile applications:

- Scalable production of highly conductive graphene-based inks

- The interaction of textiles with chemically inert or graphitic inks

The manufacturing of highly conductive glass rovings was reported using graphene-based inks, which were produced via microfluidization technique. Microfluidization is a well-established technique for applications such as deagglomerating and dispersing carbon nanotubes and oil-in-water nanoemulsions. Such method applies a high pressure (up to 207 MPa) to the entire volume of liquid to pass through a microchannel (diameter, d< 100 µm). Therefore, the benefit of this technique over other liquid-phase exfoliations of graphene (shear mixing and ultrasonication) is that it acts over the full volume of the liquid, thus achieves better yield. It is possible to develop highly concentrated graphene-based conductive inks using such technique, that can be used to produce highly conductive textile fibres.

The highly scalable microfluidization technique was also used to exfoliate concentrated graphene dispersions in water. Then a simple and readily scalable pad−dry−cure (pad-ding) method was used to coat poly-cotton textiles with graphene-based dispersion, that could potentially produce 150 m conductive e-textiles in just 1 min. The electrical conductivity of produced graphene-based e-textile was further improved by a fast compression rolling process, which provides the lowest sheet resistance (≈11.92 Ω sq−1) ever reported on any graphene-based e-textiles Table S1, Supporting Information. The coated and compressed textile was then encapsulated via screen printing of a thin protecting encapsulant layer before washing 10 times in a home laundry machine.

The research identified a simple and highly scalable way of producing ultraflexible, highly conductive, and machine washable graphene-based wearable e-textiles. The graphene-based e-textiles thus produced exhibit the lowest sheet resistance ever reported on graphene-based textiles and the highest stability to repeated home laundry washes. The multifunctional uses of such graphene e-textiles are also demonstrated such as ultraflexible wearable sensor and flexible supercapacitor. The obtained result would enable development of next generation graphene-based wearable e-textiles for multifunctional applications.

Read the full paper > https://doi.org/10.1002/adfm.202000293

Microfluidizer Technology

Microfluidizer® Processor High Shear Homogenisers are the gold standard in uniform nanoemulsions, cell disruption and uniform particle size reduction.

Microfluidizer® technology seamlessly scales up from batch to lab, pilot and even production volumes. Whether you are producing nanoemulsions, pursuing delicate cell disruptions, creating suspensions or generating cutting-edge liposomes, Microfluidizer® Processor High Shear Homogenisers is the right equipment for the job.