Microfluidizer® High Shear Fluid Processors for Scalable Solvent-Free Production of Liposomes

Microfluidizer® High Shear Fluid Processors enable the fast reduction of liposome vesicles – even with high concentration levels. Force is applied uniformly so that every millilitre undergoes the same constant, controlled shear rate and scalability is guaranteed thanks to unique Interaction Chamber™ technology.

With a wide range of Microfluidizer® processors available that are simple to use and clean, and conform to cGMP requirements, our solutions for liposome production from Microfluidics™ are trusted for research, development and production in different pharmaceutical applications across the globe.

For more information and guidance on the most appropriate model for your application, call us on +44 (0) 1954 232 776 or contact us.

Prof Yvonne Perrie, University of Strathclude, joins Microfluidics to discuss her liposome research performed with the Microfluidizer.

Solvent free production of Liposomes using Microfluidizer® technology

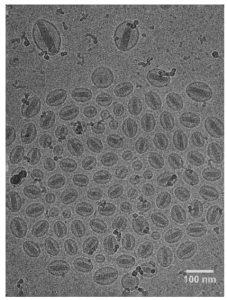

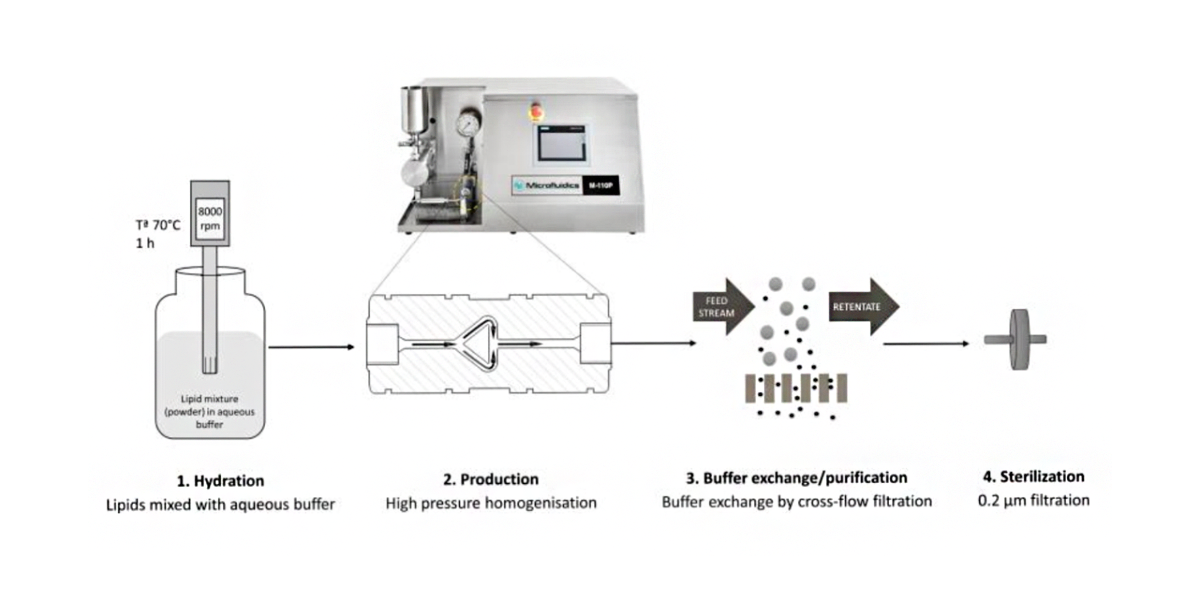

Schematic representation of liposome manufacture, buffer exchange/purification, drug loading and sterilization. (doi: 10.1111/jphp.13329)

![]() Research Paper: Scalable solvent-free production of liposomes

Research Paper: Scalable solvent-free production of liposomes

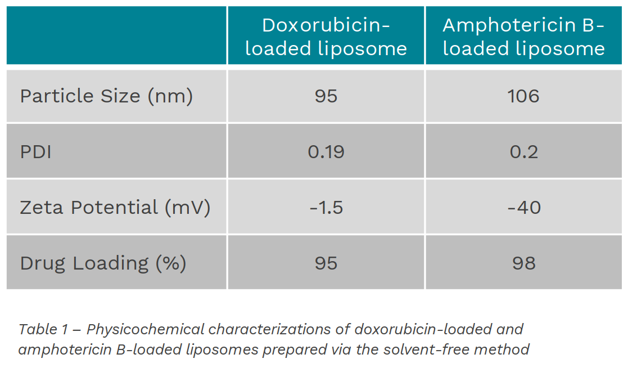

Liposome particle size, Polydispersity Index (PDI) and drug loading remain unchanged throughout the manufacturing steps.This included tangential flow filtration for buffer exchange and sterile filtration throughout 0.22 µm filters.

Drug-release testing of the doxorubicin-loaded liposomes using the USP-4 dissolution apparatus proved the desired slower release profile – 60% doxorubicin release after 6h vs. 100% release after 2h for free drug, for the PEGylated formulation.

Results shown in Table 1 indicate target physicochemical characteristics that were successfully achieved for both liposomes. These match products that are already clinically approved.

Benefits of Top down processing with Microfluidizer Instrument

- Solvent fee.

- Uniform shear produces uniform (PSD) small unilaminar vesicles (SUVs).

- Ability to reduce the size to ~40 to 50 nm.

- Different size range with different operational parameters.

- Liposome solution with therapeutic level, high concentrations directly.

- No downstream processing to concentrate the product or remove solvents.

- Concentration ranges 5 mM. (1-2 orders of magnitude higher than solvent injection method).

- cGMP ready systems with CIP and SIP capabilities.

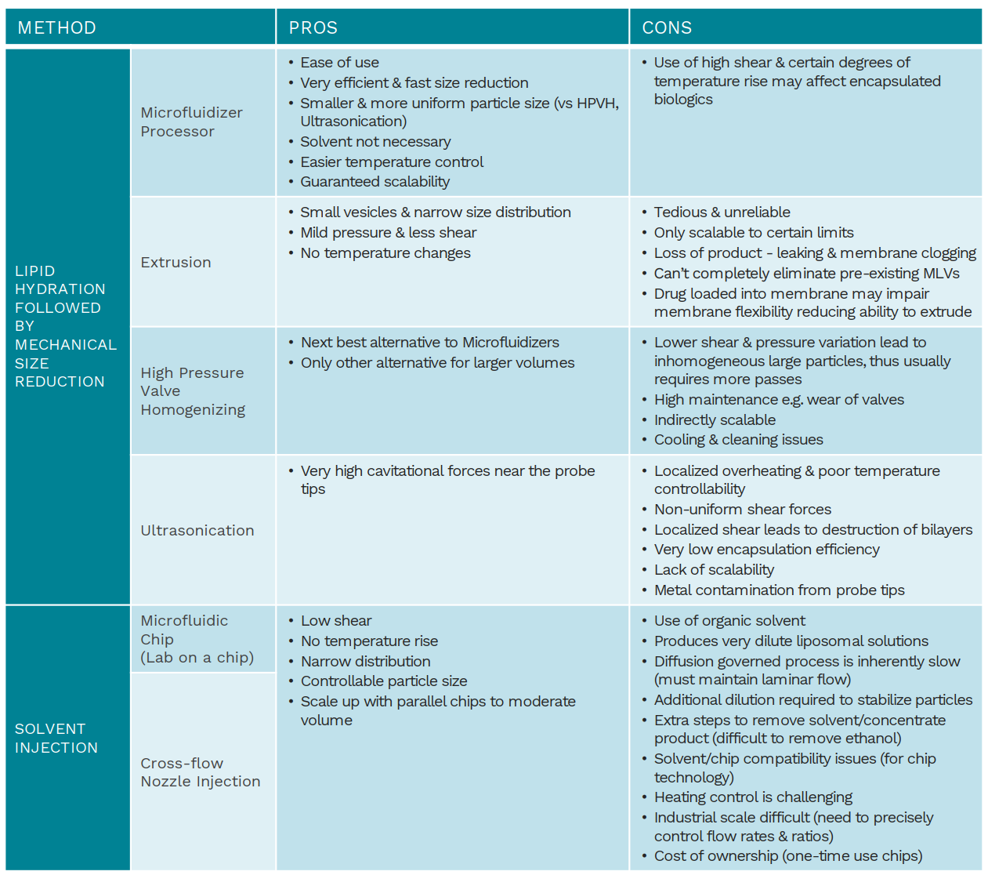

Comparison of the Microfluidizer® vs Alternative Technologies

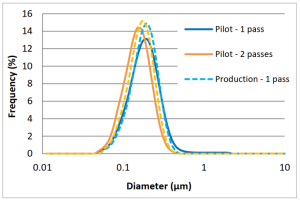

Scalability – From Pilot to Production

Scalability – From Pilot to Production

The chart here shows how the results from the pilot scale M110EH model were replicated in the M7250-30 production model. Particle sizes after both 1 and 2 passes obtained on the production machine were very close to that obtained on the pilot machine. The chart also shows how tight the particle size distribution (PSD) is that can be achieved.

cGMP Manufacturing

Microfluidics have more than 15 years’ experience with cGMP requirements for pharmaceutical applications and are trusted globally for their in-depth professional knowledge, expert support, and high-quality biopharmaceutical manufacturing equipment, for the most effective submicron particle size reduction and optimal yield for all your biotech and pharmaceutical productions.