How does a Taylor-Couette Flow Reactor Work?

What is Taylor-Couette Flow?

Taylor-Couette flow describes ordered flow observed under conditions of a fluid ‘sandwiched’ between and inner and outer cylinders where either cylinder may be rotating. This generally well understood phenomenon can be exploited to create highly efficient flow reactors as proven by Laminar’s Taylor-Couette Flow Reactors.

This novel design of reactor is highly configurable and scalable to suit specific process requirements. Reactors can be engineered in vertical or horizontal orientations, with high temperature and pressure capabilities, multiple ports for process monitoring and downstream sample injection, variable temperature control along the vessel (even the interior stirring bar) and different materials of construction to suit aggressive conditions. Reagents fed into the vessel by precision pumps may be liquids, slurries (e.g. seed particles) or even gases. Once the vessel is filled, some time and volume is required for the flow conditions to stabilise before continuous conditions are achieved.

How a Taylor-Coutette Reactor Works

Tunable shear and mixing conditions in the LCTR visible through this demonstration of air and water mixing in a see-through vessel at varying RPM.

Laminar’s Taylor-Couette Flow Reactor design rotates the inner cylinder at a variable rpm while the outer cylinder is jacketed for temperature control. Reagents are pumped in a precise flow rates at one end of the vessel, they progress down the vessel in Taylor vortices and finally reach the outlet for collection and the next stage of processing. Flow rate is controlled by reagent addition, the sum of the inlet reagent flow rates equalling the output flow rate of the reactor. This enables control over residence time and mixing ratios. The reactors feature options for multiple sample injection ports downstream of the initial reagents enabling core-shell particle coating applications.

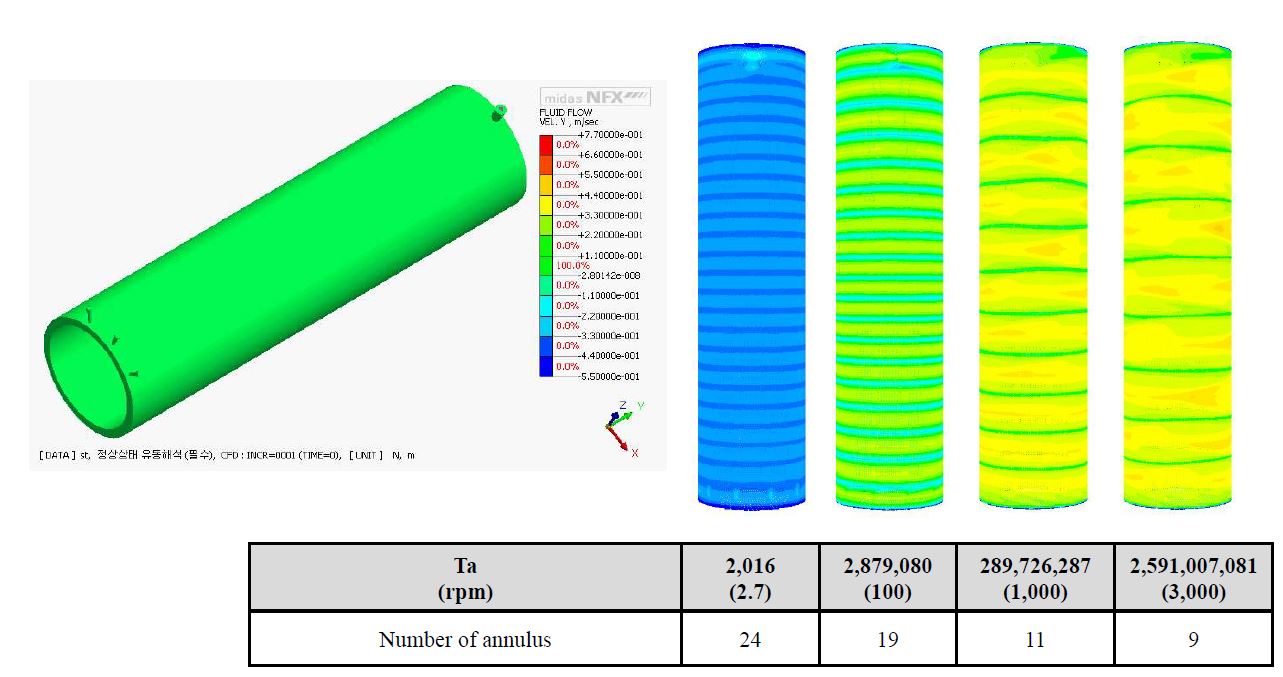

The combination of mixing force and shear rate create interesting and variable conditions for control of particle characteristics. The variable shear rate and number of Taylor ring-pairs with stirrer rpm means the balance between particle collisions and adhesion leading to crystal growth and shear rate promoting the opposite deagglomeration effect can be optimised depending on what is desirable in the end-product.

Designed to be a continuous process reactor with vessel volumes ranging from 20mL to 1,000L depending on the model, Laminar’s Taylor-Couette Flow Reactors can still be run as a batch reactor for development.

Benefits

The Taylor vortex turbulent flow results in excellent mixing force and mass transfer characteristics, this equates to a significant reduction in time for many reaction and crystallisation processes.

These flow characteristics and homogenous micro-mixing along the full volume of the reactor vessel allows the reactor to combine the benefits of plug-flow-type reactors (high purity, size distribution and control) and continuous stirred tanks (Scalability and cost) while maintaining relative simplicity of use.

Provision for measuring probes and additional injection ports along the reactor are especially useful for critical parameters in certain applications (e.g. pH for secondary battery cathode materials) which enables the user a high degree of control of particle shape, size and coating thickness. This improved particle design may lead to increased performance in the end product.

Scale-up can be achieved from lab to production scales; although the gap between the rotating bar and the vessel wall must change with the move to larger volume reactors, CFD has been employed successfully to emulate the conditions found in smaller vessels by optimising the rpm range thus ensuring a close match in conditions between development and full scale reactors. Process controls such as pH monitoring, temperature control and reagent pumping are ultimately automated via SCADA/PLC control.

Laminar Continuous Taylor-Couette Flow Reactors

Analytik provides Taylor-Couette Flow Reactors developed by South Korean manufacturer Laminar. Laminar’s patented chemical production technology commercialised Taylor Fluid Flow, developed by Couette in the early 1900s and analysed by Taylor in the mid-1900s, to develop the first Continuous Taylor Flow Reactor in 2010.

Laminar Continuous Taylor Reactors (LCTRs) have since been optimised for the manufacture of Li-ION batteries, development of nano materials and production of Graphene Oxide, and adopted by leading organisations across the globe.