About Microfluidizer® Technology

Microfluidics International Corporation manufactures unique high shear fluid processors used in the production of micro- and nano-scale materials for a diverse range of industries. Microfluidizer® technology sets the standard for nanoemulsion and nanoparticle applications, enabling leading organisations to improve process efficiency, develop interlectual property and create superior products.

Why Microfluidizer Technology?:

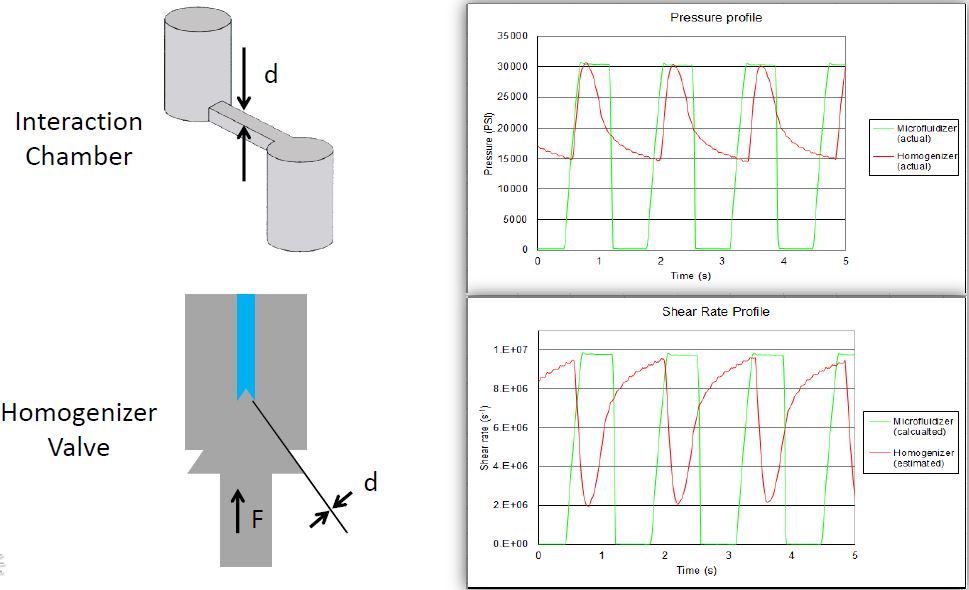

- Narrowest particle size distibution – with no moving in-line parts, the fixed-geometry interaction chamber enables a consistent and predictable processing environment with little or no downtime. The chamber combines with a constant pressure pumping system to provide a uniform processing environment for the entire product volume.

- Repeatability – reproducible results, batch to batch, day to day. Every milliliter of your sample undergoes the same processing and for this reason results are consistent and reproducible each and every time.

-

Highest Shear Force – during processing, the product stream accelerates to very high velocities, creating shear rates (up to 10-7 s-1) and impact forces within the interaction chamber that are orders of magnitude greater than any other conventional means. This makes the Microfluidizer processor ideal for applications that require extremely small particle sizes, thorough deagglomeration and high yield cell disruption.

- Scalability – in production units, identical interaction chamber microchannels are aligned in parallel to ensure uniform processing even at high volumes – often in a 24×7 continuous process. By utilising a linear scale-up method of the fixed-geometry interaction chambers, customers are guaranteed to achieve uniquely consistent results.

- High efficiency cell disruption – microfluidizer processors enable extremely effective cell disruption (often >99% rupture for E.coli in only one pass), with high protein recovery. Protein integrity is maximised by the Microfluidizer processor’s low temperature rise coupled with highly effective cooling provided by submerging the interaction chamber and placing a heat exchanger immediately downstream of the interaction chamber.

Microfluidics in Numbers

- A successful track record of over 40 years in business

- More than 4000 machines delivered to 3000 customers globally

- Used by over 1,100 pharmaceutical companies, including 19 of the global ‘Top 20’

- Chosen by 9 out of 10 top biotech organisations and 4 of the 5 largest chemical companies

Formulation and production of nanoparticles are used in a wide variety of applications:

- Pharmaceuticals – such formulations are used to improve the bio-availability,

stability, administration and efficiency of drugs - Biotech – for the efficient extraction of nucleic acids and proteins with prevention of denaturation.

- Chemicals – nanoparticle properties are used for high-tech components, coatings, inks, fuel cells,

photovoltaics, composite materials, thin film preparation and more. - Food – for encapsulation and delivery of nutraceuticals, and development and manufacture of

nanoemulsion-type products for “slimming food” markets. - Cosmetics – nanoparticles support efficiency and penetration of products through the skin barrier.

How It Works

Watch the below 4 min explainer video to find out how Microfluidizer® processors work and the technology behind the unique interaction chambers.

Microfluidizer or Homogeniser?

Do you know the difference? Read our blog article High Pressure Homogenisation vs Microfluidisation to find out!

INTERESTED IN MICROFLUIDIZER® TECHNOLOGY?

Fill out a Contact Form, call +44(0)1954 232 776 or email info@analytik.co.uk to discuss your requirements with a specialist.