Colour Standards – What are they?

The following article is based on a whitepaper written by Analytik partner Avian Technologies.

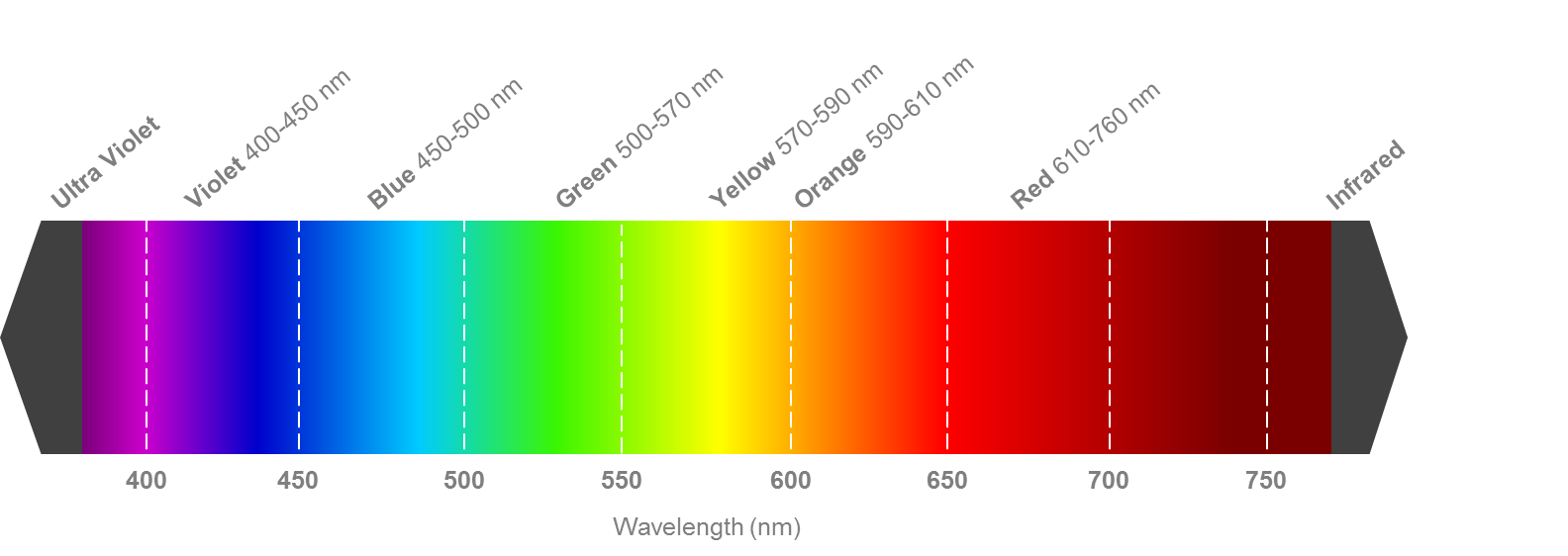

Colour Standards provide a reference point industries can rely on when measuring colour in a wide range of applications within ceramics, food, pharmaceutical, agricultural and optical industries. Colour standards can be applied to many applications from near ultraviolet, visible, to near infrared, (wavelength range of 300-800nm). It is important to select the correct properties when choosing standards as properties that are good for some applications do not work well in others.

SURFACE PROPERTIES

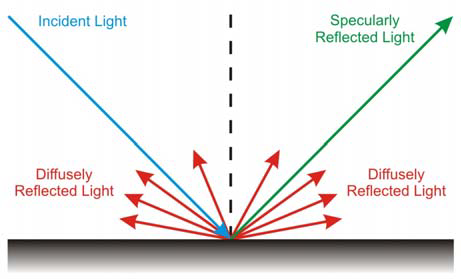

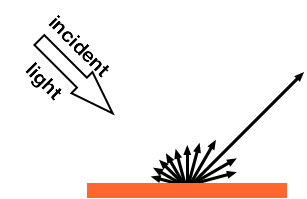

Alongside colour the next most obvious feature of a colour standard is surface properties, ranging from high gloss to matte. It is easy to make a general judgement of whether there is light reflection or if the light is diffused on a matte surface. The light that is reflected is specular light and this leaves the surface at an equal and opposite angle to that of the incident light. However, the colour of most materials is not in the specular light, so to measure the colour of a standard, the specular light needs to be ignored and the diffuse light measured in order to understand the colour of the standard.

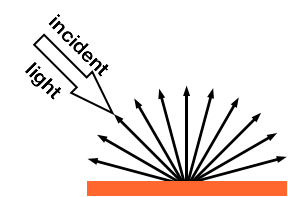

Light reflected off a matte standard will be uniformly spread across the angles of the surface and have good diffusion. Mid gloss will have a higher percentage of specular light and high gloss reflects a very high percentage of light in the specular direction. Different instruments capture the diffuse light in different ways, but the goal should be to choose a measurement that aligns to how the materials will eventually be viewed.

Matte Standard

Mid Gloss Standard

High Gloss Standard

PROPERTIES OF REFLECTANCE STANDARDS

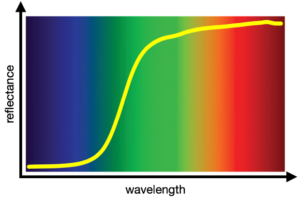

Modern instruments measure the reflectance of materials and the colour is calculated from that. Reflectance is the ratio of the light that reflects off an object to the light that is incident on the object. So, something that reflects lots of blue wavelengths and absorbs the green and red wavelengths will appear blue.

To calculate the specific shade of blue requires a mathematical transformation from the reflectance at all visible wavelengths to colour. The chart shows a yellow line indicating the reflectance of a yellow material and it shows very low reflectance in the blue and very high reflectance in the green and red. When selecting the colour range of standards it is important to consider the colour of the samples that will be measured. A general purpose may need a complete range of colours, whereas a specific task may only need a single colour reference standard. There is a neutral class of colour standard that reflect all wavelengths equally, ranging from white and greys to black.

Matte or Glossy?

Standards should preferably be matched to the samples that are being used, so if the sample is typically blue and matte, the reference standard should also be blue and matte in order to get the best measurement. However often a program is not so restricted and therefore it is worth considering that a matte surface will collect dirt and contaminants quicker than a glossy sample.

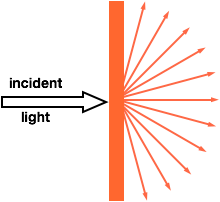

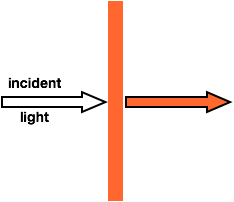

Properties of Transmittance Standards

Transmittance standards can either be scattering or non scattering. The scattering sample diffuse the light as it passes through and the transmitted light is spread in all directions. The non-scattering material does not change the direction of the light as shown in the diagram below.

Properties of Fluorescent Standards

Matching standards for fluorescent samples can be harder and the light source in instrument used for these reflectance measurements must be carefully controlled. The strength of the UV component of the light source can have a dramatic effect on the fluorescent emission which can result in two perfectly functioning instruments making completely different reflectance measurements.

Materials that might cause problems

Some materials require specialised instrumentation to deal with different properties of the material.

These can include:

- Metallics – colour is only in the specular component

- Translucent material – light is spread laterally

- Retroflective materials – colour is reflected back in the direction of the incident light

- Fluorescent and luminescent materials – presenting difficulties as described above

- Pearlescent materials – pigments change colour as a function of the angle of incident

What makes a good standard?

A good reference standard will provide stability when measuring properties over time. It will be robust to dirt, temperature changes, moisture and rough handling. If the standard is subjected to harsh conditions, it should be recalibrated more frequently and then should last for a long time.

Avian Technologies specialises in the design and manufacture of standards for optical spectrometry and other optical radiation measurements.

With the widest variety of calibrated standards available, and the ability to offer customised solutions, look no further for your calibration needs.

To read the original whitepaper, please click here.