Expanding Possibilities: Introducing the ATO IMS Module for ATO Lab Plus Ultrasonic Metal Powder Atomiser

ATO IMS: Transforming Metal Powder Production

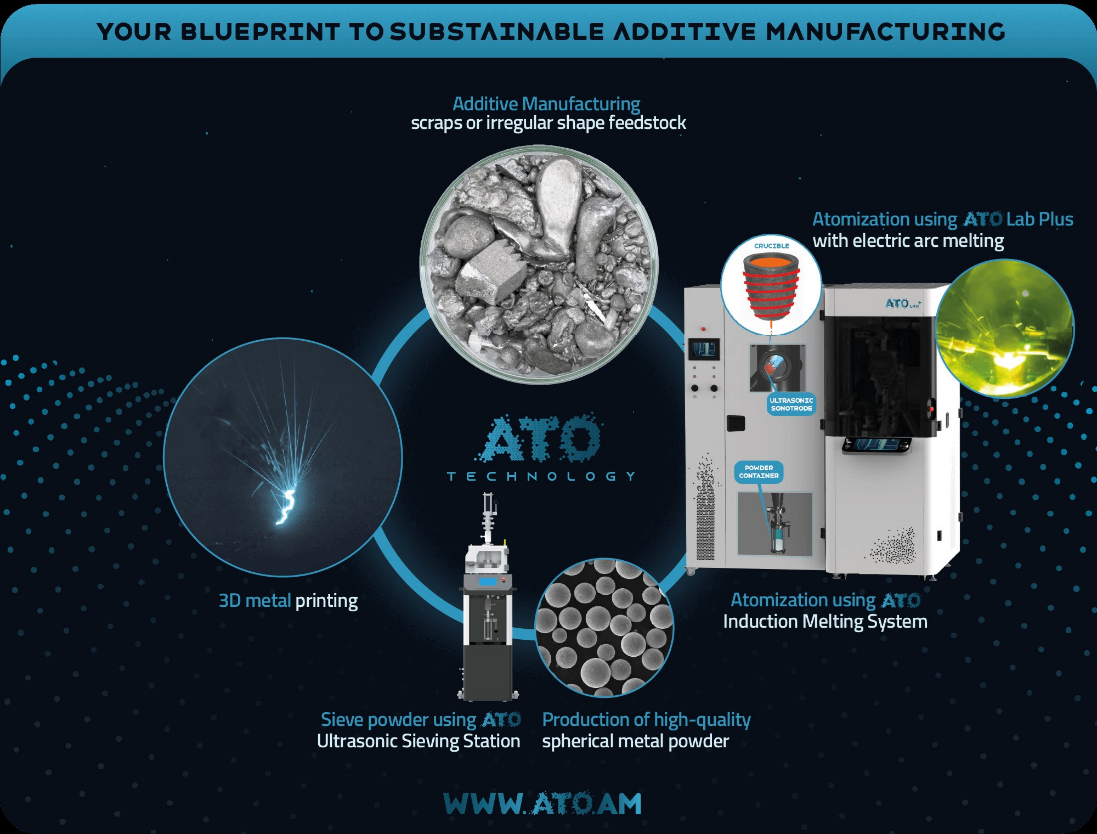

We are delighted to announce the availability of the all new ATO Induction Melting System (IMS) module, an optional addition to 3D Lab’s flagship ATO Lab Plus Ultrasonic Atomiser for in-house metal powder production. Designed as a fully compatible, integrative system, the IMS brings a host of new capabilities to new and existing ATO Lab users by enabling the atomisation of alloys with lower melting points.

Unlocking New Avenues in Additive Manufacturing

The ATO IMS module is the latest groundbreaking development from 3D Lab, creators of the patented ATO Lab Plus Ultrasonic Atomiser. It enables the melting of non-standard metal geometries like scrap, swarf, granules, pellets, and recycled print powder, which were previously unavailable to ATO users. This capability allows the recreation of fine, uniform metal powder essential for advanced 3D metal printing and additive manufacturing processes. Facilitating the atomisation of alloys with lower melting points, the IMS broadens the scope of compatible materials. The modular design ensures adaptability and versatility in handling materials, even in irregular forms, within the crucible.

Flexibility Redefined

The IMS module accommodates irregularly shaped materials in crucible or rod form, using ATO’s standard rod feeders. This not only broadens the range of input materials but also enhances atomisation efficiency, offering users unprecedented options for their metal powder production.

Seamless Integration

More than just an add-on, the IMS module becomes an integral part of the ATO Lab Plus system, fully compatible with all ATO atomisers. This commitment to modularity empowers both existing and new users to expand the functionality of their ATO Lab Plus seamlessly, tailoring their setups to meet specific needs.

Precision Control and Sustainability

Equipped with a high-definition camera, the IMS module provides real-time verification of molten metal on the main ATO Lab Plus control panel screen. The IMS touch screen ensures user-friendly and precise control over the atomisation process. Beyond performance, the ATO IMS contributes to sustainable metal powder production by establishing a closed-loop process, reducing waste and enhancing resource efficiency.

Key IMS Module Key Features and Benefits

- modular and compact design

- compatible with standard ATO rod feeders (SRFS and MRFS)

- freedom to use both crucibles and rod feeders

- ensures high chemical purity of atomised materials

- pressurised, precise molten material feeding system

- the process takes place in a sealed chamber filled with shielding gas

- double-layer crucibles to guarantee enough insulation and steady processing

- precise temperature setting system

- digital monitoring system

- easy to use by a single operator

- expands the range of material for exploration

- ideal for material recovery

- compatible with ATO Cast (Induction casting furnace designed by 3D Lab)

Read the full article here.

Discover the future of metal powder production with 3D Lab’s ATO Induction Melting System module. Learn more about its capabilities and integration possibilities in the attached IMS module datasheet.