What is Cell Disruption?

Cell Disruption, or Cell Lysis, is the process of breaking cell wall and/or membrane to release intracellular fluids containing molecules or particles of interest, such as proteins or viruses. The primary goal of cell disruption is to lyse the suspended cells and recover the maximum possible viable yield of the molecules/particles of interest.

Cell Disruption Methods

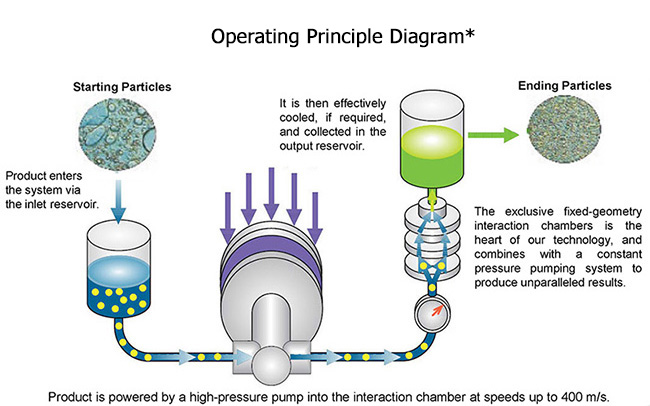

Microfluidization: Sometimes also referred to as High Shear Homogenisation, the Microfluidizer® processor method of Cell Disruption provides superior quality and usability of ruptured cell suspensions for increased yield. Microfluidizer processors are ideally suited for effectively rupturing cells requiring different levels of shear.

High Pressure Valve Homogenisers: High-pressure valve homogenisers are a widely adopted method for cell disruption. Prices are typically comparable with Microfluidization although cooling, cleaning, valve wear and scalability can be an issue.

French Press: Using a French Press for cell disruption involves a manually controlled valve releasing pressurised fluid from a pressure cell, resulting in cell rupture. This method is not scalable or repeatable and French presses can be difficult and time-consuming to clean, which must be done after every sample. Most manufacturers have now discontinued production, however some units are still in use.

Ultrasonication: This method of cell disruption or cell lysis uses cavitation forces. Often used for very small sample volumes, the cell suspension is sonicated with an ultrasonic probe. Disadvantages of this technique include local high temperatures, resulting in low yields; scalability challenges; and noise. The advantages are low equipment prices and the ability to process small scale volumes.

Freeze-thawing: Subjecting cell suspensions to variable temperatures is a method which can be used to rupture cell walls. This cell lysis technique is difficult to reproduce as results can vary widely, and thus is only suitable for very small samples.

Chemical Cell Lysis: This approach to cell disruption involves adding chemicals that soften and rupture the cell walls. Chemicals can be costly and thus scalability is limited. These chemicals also contaminate the preparation which is often undesirable.

Mortar and Pestle: Manually grinding a cell suspension is a laborious process that can take several minutes, making it not scalable and not very repeatable, suitable for small lab samples only.

Media Milling: Contamination by media and temperature control are difficult, but otherwise media milling can be an effective method for disrupting many cell types.

Cell Disruption using the Microfluidizer® Method

To find out more about using Microfluidizer® technology for cell disruption, view the below video:

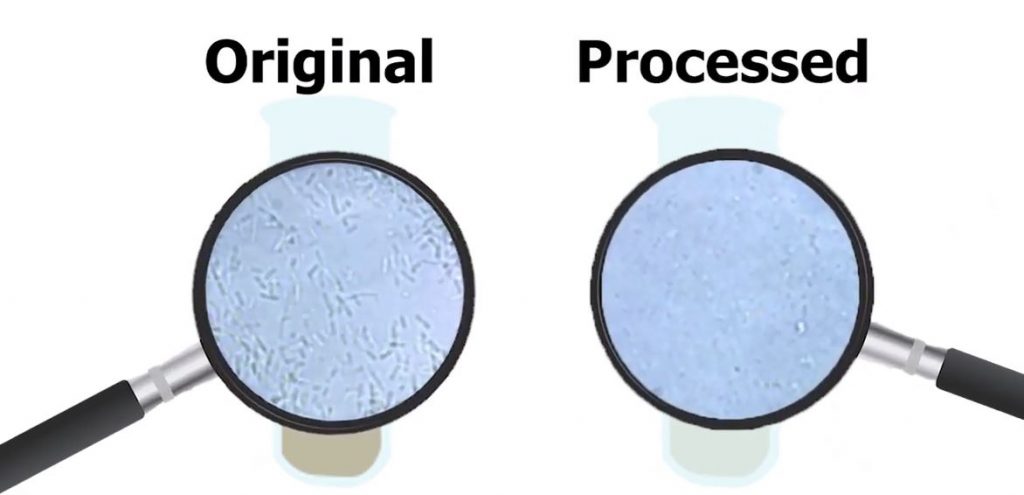

Microfluidizers are ideally suited for efficient cell rupture of bacterial, yeast, mammalian, plant, insect, fungal and algae cells while ensuring high protein recovery. The variable process parameters allow users to apply the lowest shear rates necessary to reach target rupture percentage, while avoiding denaturing intracellular contents.

For cells that do not secrete these intracellular contents, it is vital to lyse the cell to liberate the contents. It is important to not denature delicate proteins or viruses by elevation of temperature or excessive shear rates. Microfluidizer processors are extremely efficient at rupturing all cell types with minimal denaturation due to the efficient application of shear and control of temperature.

Microfluidizer® Cell Disruptors

We provide a wide range of Microfluidizers from US manufacturer Microfluidics. Fully scalable, Microfluidisation provides a fast, easy and effective method of cell lysis.

To find out which Microfluidizer® is most suitable for your requirements, contact us or visit our Solutions for Cell Disruption page.